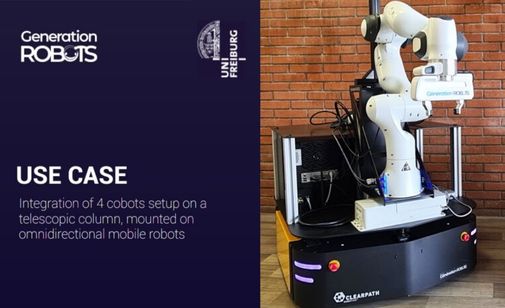

CASE STUDY

Integration of 4 cobots setup on a telescopic column, mounted on omnidirectional mobile robots

Generation Robots provided four mobile manipulator robots, equipped with omnidirectional platforms, telescopic columns, and robotic arms for the University of Freiburg, a renowned institution in the field of research.

This project aimed to develop robotic assistance for household tasks, particularly for the elderly or people with reduced mobility.

To learn about all the technical challenges of this project, download our case study 👇

Challenges successfully overcome

- Equipment selection

-

Technical challenge #1

Emergency button propagation -

Technical challenge #2

A telescopic column not designed for mobile robots -

Technical challenge #3 :

An arm that requires an operating voltage of 230v -

Technical challenge #4 :

Insufficient range of motion in the robot arm -

Technical challenge #5 :

Teleoperation & battery life of the robotic platform

Download your case study