Trainees at Deutsche Bahn can now use Niryo to familiarise themselves with robots.

How is Deutsche Bahn preparing its apprentices for tomorrow?

Deutsche Bahn AG wants to ensure its trainees are fully prepared for the practicalities of their work. And effective, automated production processes are already requisite for industry.

This is why the company is teaching its future specialists the principles of efficient lean production as part of their initial training. Working with robots gives a clearer understanding of automatable and lean production processes.

Putting this into practice: where better than an in-house training workshop?

From their very first year of training, future specialists at Deutsche Bahn must already be familiar with automation of dangerous and difficult work.

Interview with Marcel Häßler, Project Manager, DB Training, Learning & Consulting

Mr Häßler, why did you choose Niryo as your “training robot”?

Last year, in 2019, we equipped our 26 training workshops with 3D printers. They integrate seamlessly into our Deutsche Bahn lean production process. We want to use this approach to optimise our manufacturing operations. Our trainees can now use these printers to familiarise themselves with the 3D printing process, make changes to spare parts and even print parts themselves.

Niryo’s parts are 3D printed, so this fits very well into our training and learning system. They’re easy to use and so within easy reach of all our apprentices.

We also wanted to buy 2 robots for our 26 workshops. We have about 1,200 apprentices, and they’ll all come into contact with a robot in the three to three and a half years that they spend with us. We would never have been able to use industrial robots, they’re too expensive.

How did the first “meeting” between Niryo and your workshop apprentices go?

They were delighted. The general impression was: “Great, we can finally use robots in our workshops!”

The 240 trainers involved in our workshops are currently assembling and testing the robots, sometimes even with the help of apprentices. The explanatory videos are proving particularly useful for this. The instructions are also helpful, we use them in the training too.

The only downside for some colleagues was that some documents were initially available in English only. But I don’t find that’s a serious problem, because it gives apprentices a chance to learn technical English during their training too.

Are the manufacturer’s materials sufficient for learning?

The materials provided help you to get started, quickly and efficiently, but DB Training, Learning & Consulting will be creating its own tasks with in-house solutions over the next few weeks.

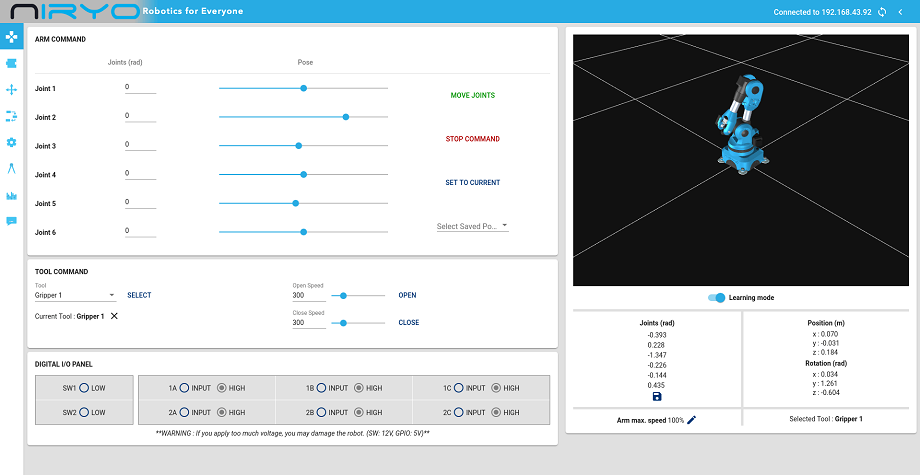

The modules involving Niryo will be integrated directly into our existing training plans. These modules have been tailored to their content. It might even be possible for apprentices to control the conveyor and the robots from their first year in learning mode. In the third year, once they have gained more specialised knowledge, we may be able to integrate the robot into the Siemens control system. The robot can also pick up parts and put them in different places. We can use Niryo’s camera system for this.

In addition to tasks, we’ll be compiling brief instructions explaining how to use Niryo on the computer network. You don’t have to install any software, so using Niryo in workshops is very easy. It’s a huge advantage.

What are the advantages of using robots in training workshops?

Trains are purchased ready for use from Siemens and tracked by our experts throughout their lifetime. The parts are very large and heavy, often weighing several tonnes. They are disassembled and assembled by hand, experts are helped only by cranes and forklifts.

If tomorrow’s specialists, our current trainees, are familiar with these robots and their possible uses from the outset, it will be a real advantage. It remains to be seen how much robots and exoskeletons will be able to help humans!

Thank you very much, Mr Häßler!

We will publish a second follow-up article after a few weeks’ use of Niryo.

Contact DB Training, Learning & Consulting: servicemanagement@deutschebahn.com