-

Visit our shop

Visit our shop

-

English

Key takeaways:

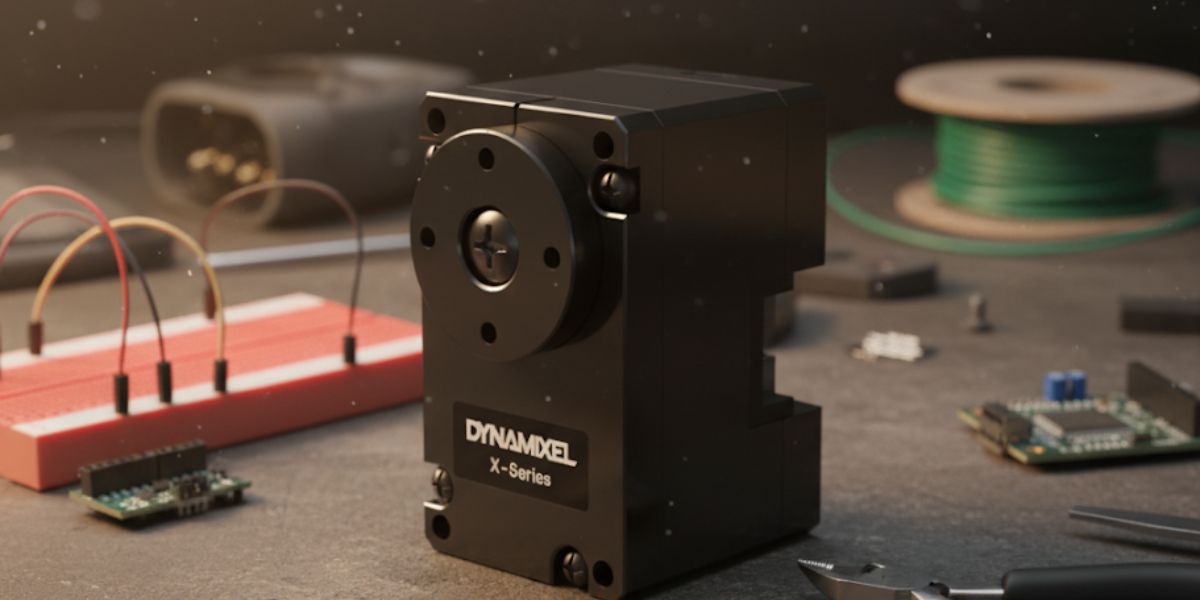

Dynamixel servos and aerospace

Dynamixel-P servos to build Mars rovers

Special offer on Dynamixel-P servos — across the full range.

Before choosing a reference, keep two questions in mind:

It’s not the most visible part of a project, but it’s often the one that most impacts stability in real conditions.

In robotics, load is not just a mass. It also depends on:

This is common in prototyping: an axis seems properly sized in static conditions, then ends up at its limit as soon as you move fast or run repetitive cycles.

On a prototype, position control is enough in many cases. But as soon as there is interaction (contact, grasping, compliance, mechanical safety), the question of force quickly comes up: limiting stress on mechanics, avoiding certain behaviors under load, or stabilizing a motion.

This isn’t only software. It also influences the required margin and the choice of series.

Without going into every variant, here’s a simple summary:

Either way, the objective is the same: avoid a setup that looks fine in a demo but turns unstable when you push the pace or the payload.

This model is often chosen for small mechanisms and prototypes where the goal is to validate a kinematic chain or a concept without making the system heavier. It’s a good fit when you multiply axes and prioritize compactness.

This model comes up regularly in compact multi-axis prototypes when you’re looking for a versatile servo for light to medium axes. It’s often selected as a baseline when the priority is to build a clean system without oversizing.

This model is generally preferred for more demanding axes, especially when payload, accelerations, or repeated cycles require more margin. It’s often used as soon as an axis lifts a significant load and dynamic performance becomes a key criterion.

Our entire range of Dynamixel servos is on promotion (including the XL330-M077-T, XC330-M288-T and XM430-W350-T).

Vanessa Mazzari

Marketing Manager at Génération Robots