Get a quote in only 3 steps!

1. Add the items you are interested in to your cart

2.Go to your cart

3.Click on GENERATE A QUOTE

Tous vos devis sont accessibles à partir de votre compte client.

The servomotors have to be linked to a main controller (CM-700, CM-5, CM-510 or CM-530) to be commanded. The progams are made with RoboPlus, which allow really easy programmation, without much previous knowledge.

The most recent main controllers support embedded C and there is a SDK for you to developp your own applications.

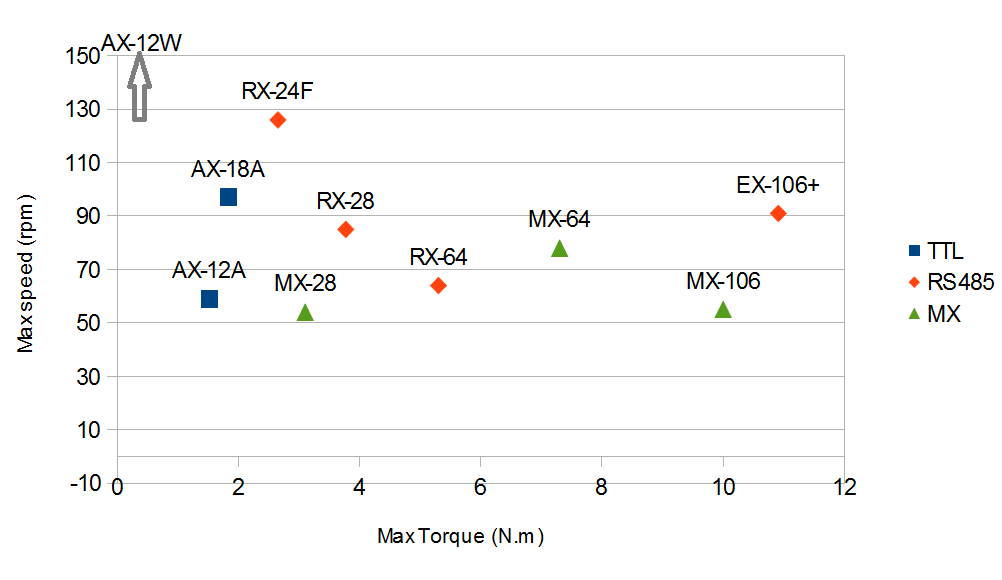

The AX-18A actuator has a better speed than the AX-12A actuator.

This document offers an overview on the characteristics of all the Dynamixel servomotors.

The chart below compare the Dynamixel actuators on their performance. Servomotors are differentiated by communication type (and the MX range proposes both protocols).

Check that your Dynamixel servomotor is correctly configured. Do not hesitate to re-flash it with the ROBOTIS Software Roboplus. After re-flash remember to re-configure it. If the issue is not solved, contact us for an advanced support.

The motor is probably not well mounted. Check that you correctly mounted the horns by respecting the mark.

There is probably a mechanical issue with the Dynamixel servomotor. You can directly contact us to get more advance support.

Check your power supply and the system cabling (try with a different servomotor). You can also reset the servo. If nothing works, the best solution is to go through the Dynamixel servomotor checklist!

The 1.0 protocol is dedicated to the Dynamixel AX and MX series. Protocol 2.0 is for the X and Dynamixel Pro series. Protocol 2.0 control tables include PID controls which allow for more precise adjustment of the servo motor movements. Protocol 2.0 can be updated on MX series servo motors. You can refer to the protocol 1.0 and protocol 2.0 pages for more informations.