Get a quote in only 3 steps!

1. Add the items you are interested in to your cart

2.Go to your cart

3.Click on GENERATE A QUOTE

Tous vos devis sont accessibles à partir de votre compte client.

The Dynamixel XC430-T240BB-T servomotor is a robust robotic component, offering a variety of operating modes, easy-to-assemble configuration, and energy optimization due to reduced current intensity.

The XC430 servomotor series from ROBOTIS is enriched with the addition of the XC430-T240BB-T model. This model is equipped with discreet magnetic encoders allowing for continuous 360° rotations at a maximum speed of 70 rotations per minute. It provides an impressive torque of 1.9 N.m at a 12V voltage, while maintaining a very light weight of 65 g. This combination of power and lightness makes it a versatile and highly efficient servomotor.

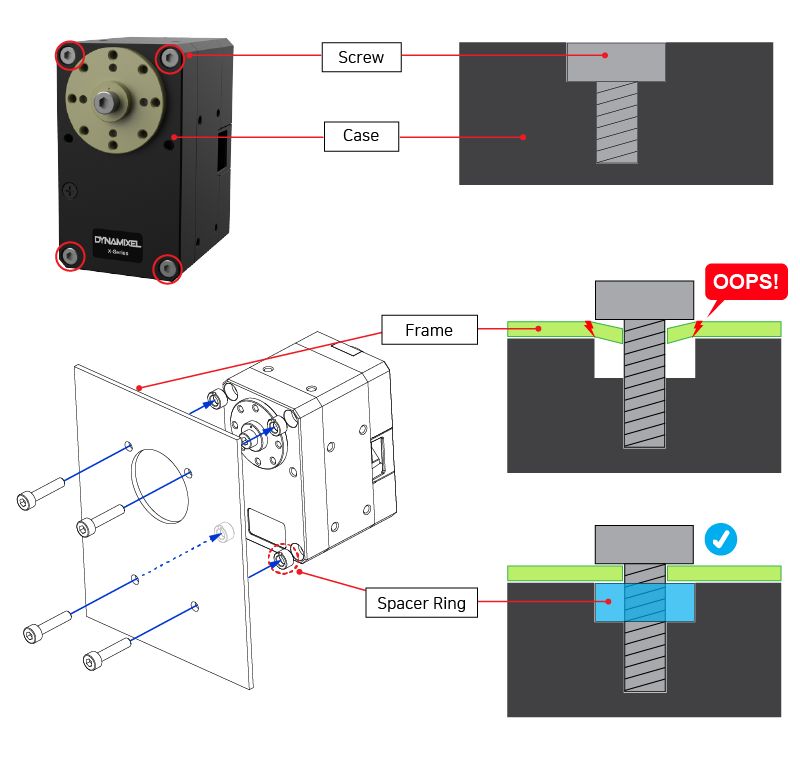

ROBOTIS has reworked and improved the cable management system in its Dynamixel X series, which enhances the reliability of the product. Unlike the AX/MX series where cables are connected at the back of the servomotor, this innovation reduces stress on the cables and minimizes their exposure.

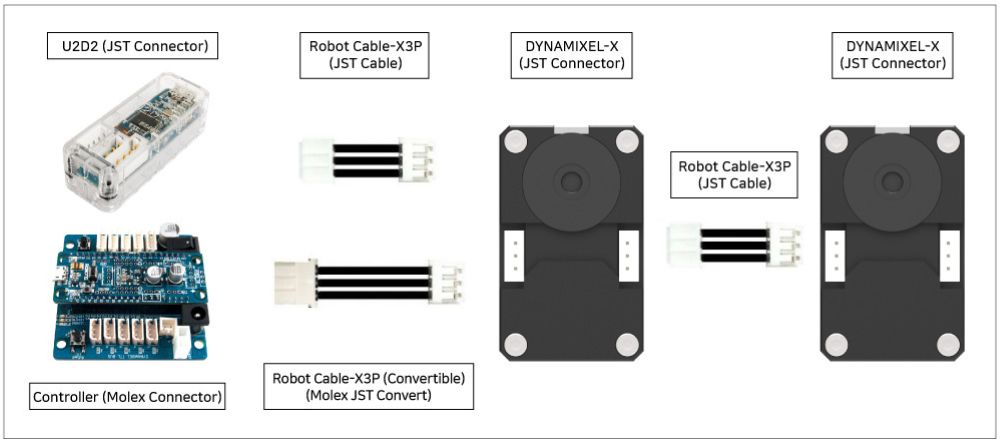

What's in the box

Find the right information about the Dynamixel XC430-T240BB-T servomotor with this list of links specially gathered for you:

Check that your Dynamixel servomotor is correctly configured. Do not hesitate to re-flash it with the ROBOTIS Software Roboplus. After re-flash remember to re-configure it. If the issue is not solved, contact us for an advanced support.

The motor is probably not well mounted. Check that you correctly mounted the horns by respecting the mark.

There is probably a mechanical issue with the Dynamixel servomotor. You can directly contact us to get more advance support.

Check your power supply and the system cabling (try with a different servomotor). You can also reset the servo. If nothing works, the best solution is to go through the Dynamixel servomotor checklist!

The 1.0 protocol is dedicated to the Dynamixel AX and MX series. Protocol 2.0 is for the X and Dynamixel Pro series. Protocol 2.0 control tables include PID controls which allow for more precise adjustment of the servo motor movements. Protocol 2.0 can be updated on MX series servo motors. You can refer to the protocol 1.0 and protocol 2.0 pages for more informations.